02/14/2013 6:00 P.M.-6:20 P.M.

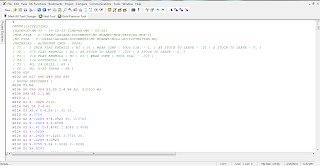

I created two dimensional lines to create the shape of my solid model.

Step 2:

02/14/2013 6:20 P.M.-7:20 P.M.

I used my two dimensional lines to extrude my box and create a cavity for the box.

Step 3:

02/15/2013 8:30 A.M.-10:30 A.M.

I added details to make the part machinable. By adding Fillet radii, it creates a shape that will allow me to create machinable tool paths.

Step 4:

02/15/2013 10:30 A.M.- 12:30 P.M. 5:00 P.M.-7:30 P.M.

02/16/2013 8:30 A.M.- 10:30 A.M. 2:00 P.M.- 5:30 P.M.

02/17/2013 9:00 A.M. - 10:00 A.M. 12:00 P.M.- 1:00 P.M.

Determined material stock size that part will fit in and be able to be machined from. Material needs to be over sized in order to be held in a vise. I then started creating tool paths for the first operation.

Rough periphery cut:

Roughed out pocket:

Finished inside pocket and periphery. Also drilled and tapped cover mounting holes:

Step 5:

02/17/2013 4:30 P.M. - 7:30 P.M.

I then flipped my model over to complete the second and final operation. I milled off the excess material and created a deburring operation to eliminate all sharp edges. I also personalized the box by engraving my name to the bottom. This took 3 hours.

Step 6:

02/18/2013 8:30 A.M. - 11:30 A.M 6:00 P.M.- 9:00 P.M.

I followed the same steps (drew solid model and created tool paths) to create the cover for my box

Here is the view of my box with the cover on it.

Testing to see if it could be made, no errors were shown on the program.

All this is to create NC coding that the CNC mill can read.

LITERAL

“I, Ariana King, affirm that I completed my independent component which represents 30 hours of work.”

(b) Cite your source regarding who or what article or book helped you complete the independent component

My mentor was the best in helping me complete this component.

(d) Explanation of what you completed.

I created a 2D image of a box with a lid and holes for screws in MasterCam which generated the NC coding after both the model and tool paths were completed.

APPLIED

By better understanding the program, I can better handle the program itself,reducing mistakes, and increasing the speed in which I can generate a program. This helps provide validity to my first answer, which was having a sound understanding of how the specific program a machine programmer is using works. Creating this box allowed me to become familiar with some of the tools of the program as well as how tool programming works.