1. How can a machine programmer best produce quality airplane

parts in the aerospace industry?

2. How do different types of metal effect the way you program a specific airplane part?

3. Why is it so important to track a heat lot on material used for these parts?

4. What types of coatings and paints are commonly used and how does this affect close tolerances?

5. What are some of the tolerancing differences between commercial airplane parts and government airplane parts?

6. What other outside processes are most commonly used and why can't we accomplish those with a CNC machine?

7. How do you determine what goes on a CNC mill and what goes on a CNC lathe?

8. On a part that has multiple operations, how is quality sustained throughout each operation?

9. What is the process used when quoting a new job?

10. What are some examples of various types of workholding?

11. What is the protocol when a part has changed revision?

12. How do you determine what is the most efficient machine, be it a mill or a lathe, to make a specific part?

13. Some metals can be cut without the use of coolant. What are those metals and what kind of tools are used to cut them?

14. When making a set up sheet for the machinist to use, what kind of information is important to have on it?

15. What are some programming techniques used to achieve a good surface finish? How do these techniques differ from material to material?

16. When running a job, what is more important? Tool life, or run time?

17. All these cutting tools are extremely sharp and when cutting metal, sharp chips are flying out at high speeds. Also, the part itself has corners that are razor sharp. How can a program minimize work related accidents?

18. How important is it to have a clean and tidy shop floor? How do you sustain a tidy shop floor? How does this tie into making quality parts?

19. In what ways does production work with quality from start to finish on each job?

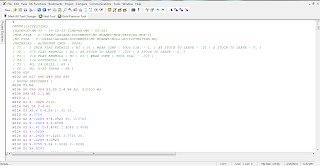

20. What is the best way to learn CNC programming using a CAM system?